Electrostatic charging, or triboelectric effect, can be described as an accumulation of electric charge in an object or body after getting in contact with another object or body. Probably one of the most known cases of electrostatic discharge occurrence is that of a charged human body get-ting in contact with a metallic object. Shortly before the body actually touches the object, a rapid discharge occurs and a spark can be noticed (in the dark, the spark may also be visible). The accumulation of charge in the human body can have multiple causes: touching an already charged object, walking with shoes that isolate the body from ground especially in dry air, wear-ing synthetic clothes, etc. Strength of the electrostatic discharge in this case depends on the level of charge accumulated, speed of human hand/finger when approaching an object (or another body) and environmental conditions (atmospheric pressure, temperature, humidity). In electric terms, the discharge is characterized by the charging voltage (for example it is considered that a human body can charge up to 15 kV in IEC 61000-4-2, a conventional value for air discharge mode) and the discharge current, that can reach a first peak of 30 A when 8 kV are discharged in contact mode). The discharge current, an exponential waveform, is also characterized by other parameters like rise time and current level at 30 ns and 60 ns.

Hence, what is electrostatic discharge? ESD is a phenomenon through which a previously charged body or object transfers very quickly accumulated charge to another body or object with which it comes into contact. The fast charge transfer can be unpleasant for the human body and has the potential to disturb or even destroy sensible electric and electronic circuits or components.

In order to prevent faults or destruction of circuits and components, ESD testing should be per-formed in the design phase of a product, and for certification purposes (before being introduced into the market) as regulations across the globe generally require electric and electronic products to comply with a series safety and EMC (electromagnetic compatibility) standards.

How to perform ESD testing?

ESD testing requires typically an ESD generator (sometimes called simulator), accessories and a proper environment. In IEC 61000-4-2, the test setup for table-top equipment may include a ground reference plane, test table with horizontal coupling plane, vertical coupling plane, grounding cables with bleeder resistors and insulating support. The disturbance is then applied to the points defined in the test plan directly, or through the horizontal and vertical coupling planes indirectly. During the tests, environment parameters (temperature, humidity and atmos-pheric pressure must be maintained in the limits defined by the standard.

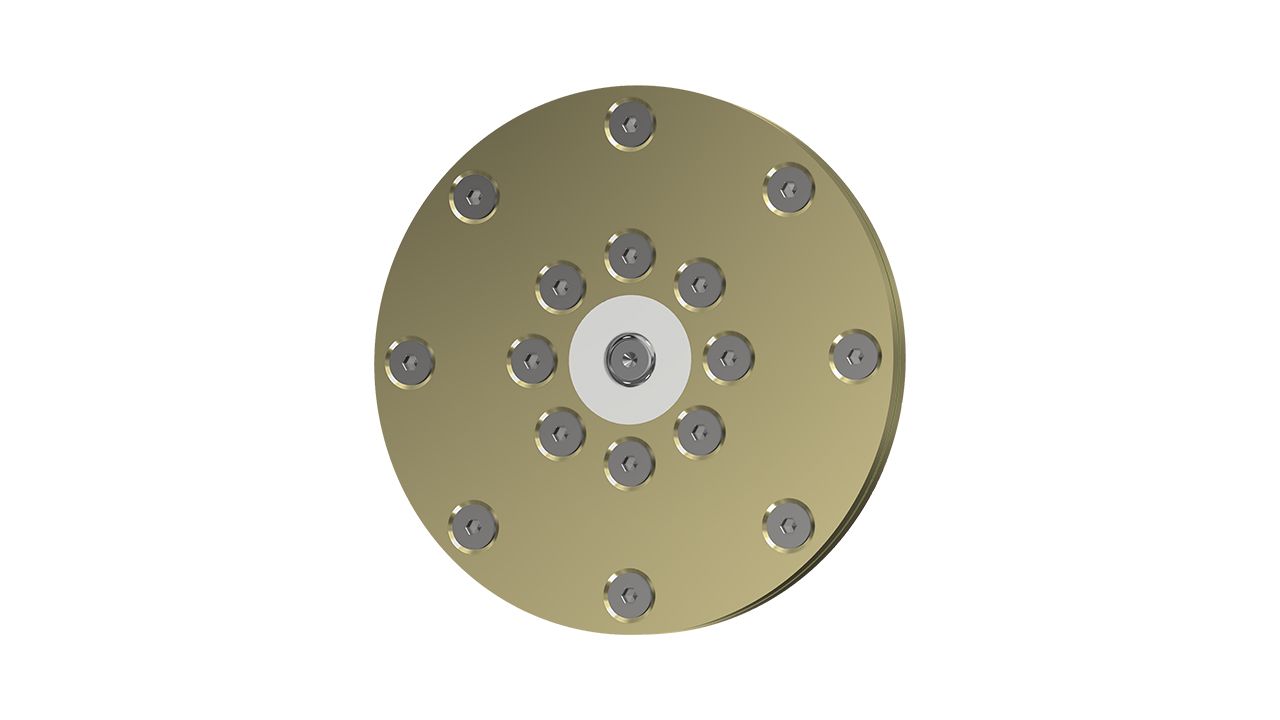

The test equipment should be verified either before each test or periodically. While IEC 61000-4-2 describes a more simple verification procedure, standards like MIL-STD-461G CS118 require verifi-cation of the ESD generator voltage with an electrostatic voltmeter and verification of the ESD dis-charge current waveform in a current target. In this latter case, it is expected to include the re-sults of verification in the test report.

Test equipment for ESD testing

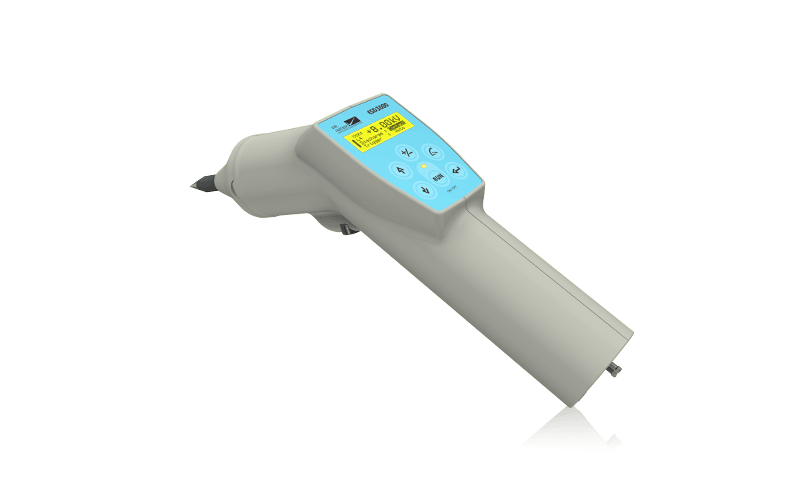

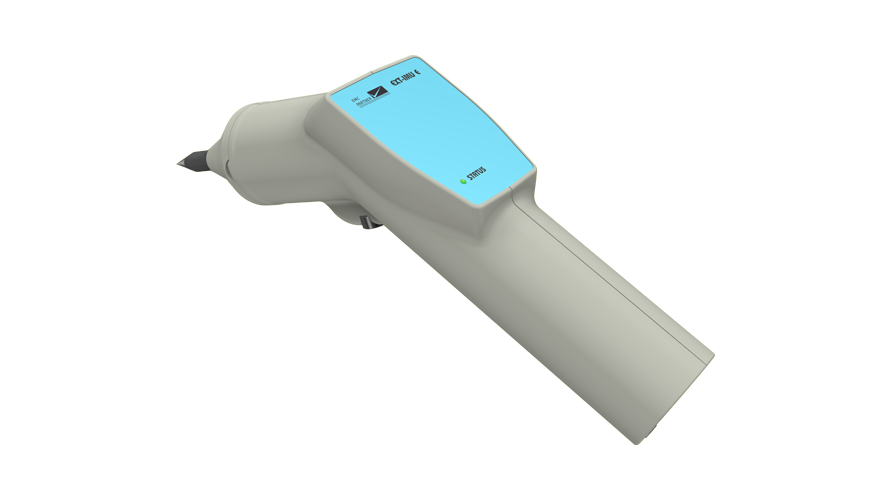

EMC PARTNER provides a very flexible solution for ESD testing, based on the ESD3000 mainframe. Different discharge modules can be easily interchanged to meets requirements from standards like IEC 61000-4-2, ISO 10605, MIL-STD-461G CS118, DO160G Section 25 and many others. Together with suitable accessories, ESD3000 can be employed for tests on explosive devices according to MIL-STD-331.

ESD3000 is probably one of the few mainframes on the market that can be initially purchased for tests up to 15 kV and easily upgraded on site (no return to the factory, hence reducing down time) subsequently to meet requirements up to 30 kV. Its modular architecture, without a separate base station and overall reduced weight, turns the ESD3000 into an extremely versatile and portable solution.

IEC 61000-4-2 | Electromagnetic compatibility (EMC) - Part 4-2: Testing and measurement techniques - Electrostatic discharge immunity test |

ISO 10605 | Road vehicles |

MIL-STD-461 / CS118 | MIL-STD-461 / CS118 |